Product Details

PHS Series

PHS-320

- Model:PHS-320

About this product

◆ Can dry rapidly, evenly at low temperature.

◆ The rate of broken rice would be low and the appearance rice will be beautiful, achieving high milling yield.

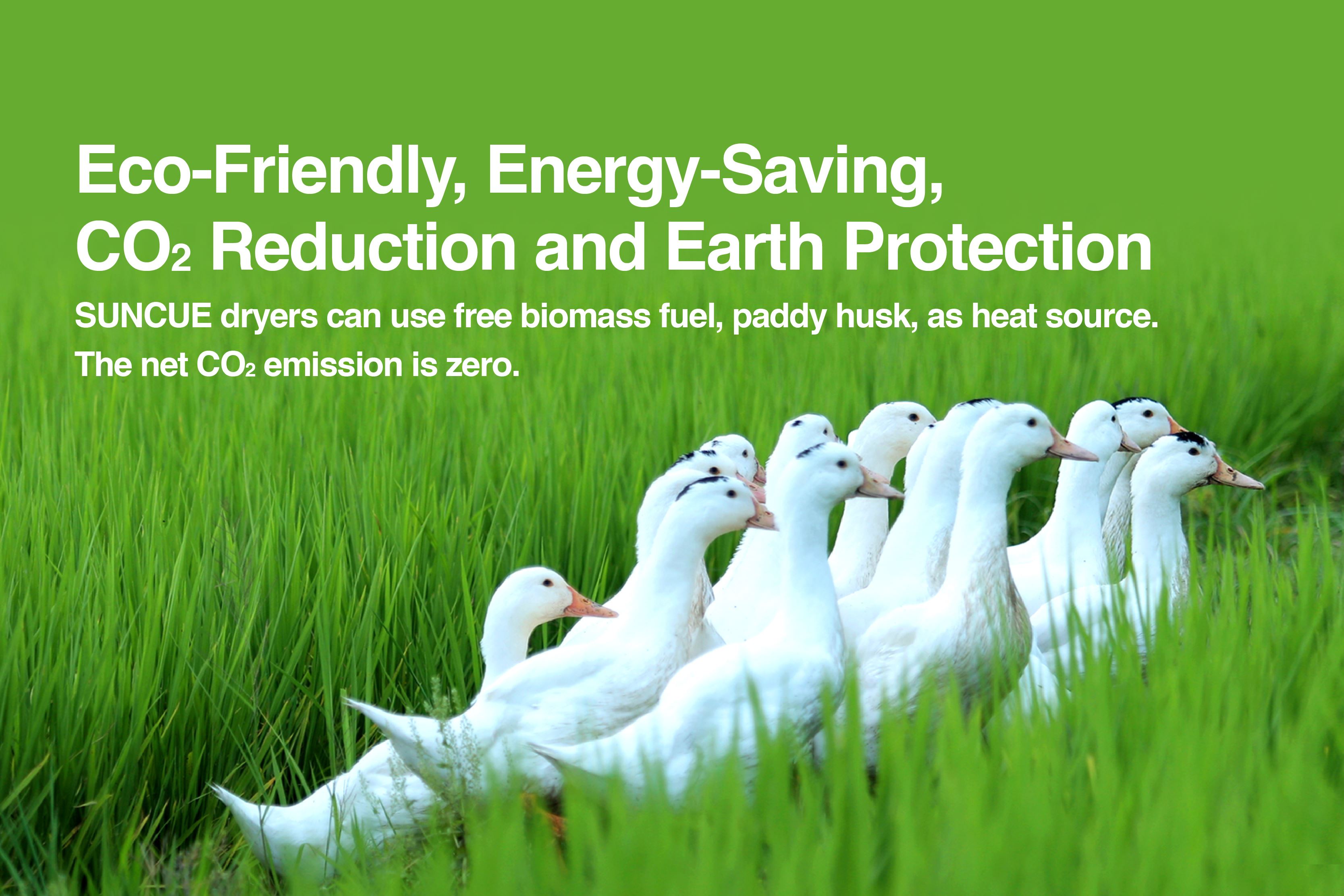

◆ Can use rice husk as biomass fuel to minimize drying costs.

◆ The rate of broken rice would be low and the appearance rice will be beautiful, achieving high milling yield.

◆ Can use rice husk as biomass fuel to minimize drying costs.

Product Introduction

PHS-320 Series

• The low-temp., even and speedy drying minimizes broken rice, raises milling rate and produces beautiful rice.

• The entire dryer is designed to be strong and sturdy, making it suitable for heavy-duty.

• With foolproof design, users can produce high-quality rice from the 1st, 100th to 1000th batch.

Small-package rice consistent in quality will be available to customers.

• Automatic moisture control prevents over-drying and weight loss.

• By using self-milled free rice husk, users no longer need to spend on diesel, natural gas or electricty as dryers' heat sources.

Multiple models with various fuel options availabl

Application

Specifications Unit mm

*Use high-quality kerosene or premium diesel only

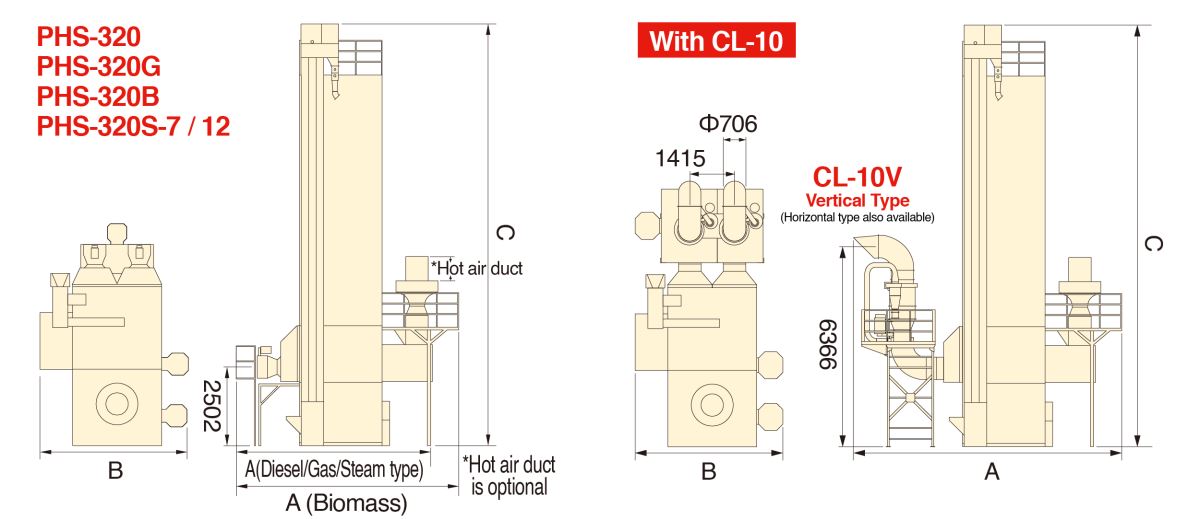

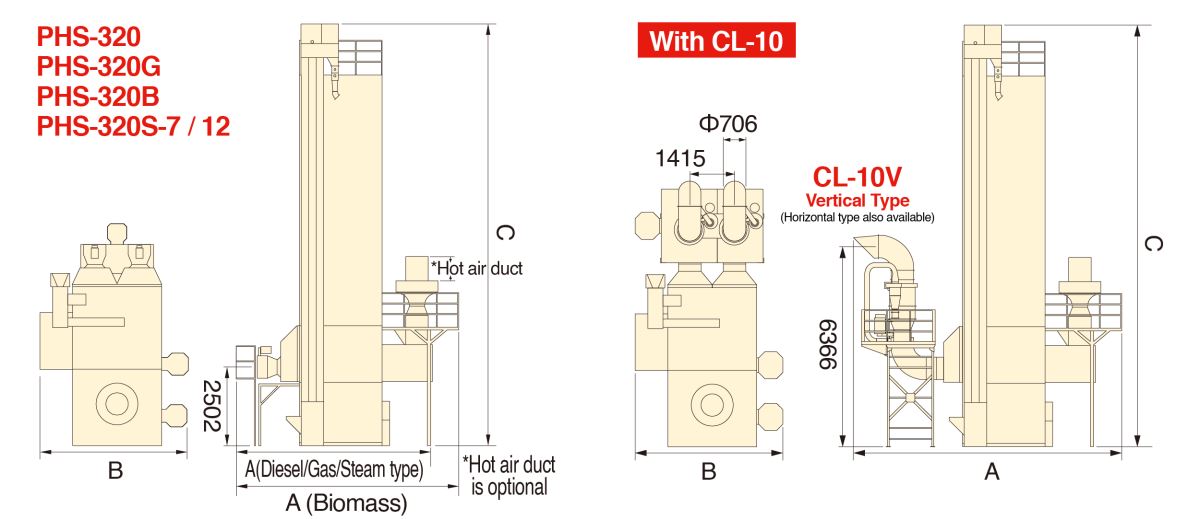

Dimensions

• The low-temp., even and speedy drying minimizes broken rice, raises milling rate and produces beautiful rice.

• The entire dryer is designed to be strong and sturdy, making it suitable for heavy-duty.

• With foolproof design, users can produce high-quality rice from the 1st, 100th to 1000th batch.

Small-package rice consistent in quality will be available to customers.

• Automatic moisture control prevents over-drying and weight loss.

• By using self-milled free rice husk, users no longer need to spend on diesel, natural gas or electricty as dryers' heat sources.

Multiple models with various fuel options availabl

| Heat Source | PHS-320 Series |

| Diesel | ● |

| Gas | ● |

| Biomass | ● |

| Diesel & Husk Dual | ● |

| Gas & Husk Dual | ● |

| Steam | ● |

Application

Specifications Unit mm

| Item | PHS-320 | ||

| Heat Source | Kerosene or Premium Diesel* | ||

| Type | Gun type | ||

| Combustion Approx. liter/hr | 17.5~35 | ||

| Capacity Approx. kg | Paddy 1 liter=560g | 7,800~32,000 | |

| Wheat 1 liter=680g | 9,600~38,800 | ||

| Corn, Animal Feed 1 liter=690g | 9,600~39,400 | ||

| Dimension L(A)×W(B)×H(C) mm | Without CL-10 | 5,871×4,871×13,410 | |

| With CL-10 | Horizontal Type | 8,201×4,871×13,410 | |

| Vertical Type | 7,291×4,871×13,410 | ||

| Net Weight Approx. kg | Without CL-10 | 6,360 | |

| With CL-10 | Horizontal Type | 7,402 | |

| Vertical Type | 7,703 | ||

| Power Consumption kW | Without CL-10 | 13.5 | |

| With CL-10 | 21.05 | ||

| Function Paddy | Loading Approx. mins | 55 | |

| Discharging Approx. mins | 50 | ||

| Drying Rate %/hr | 0.5~1.5 | ||

| Electricity | 3P, 220V/380V/415V/440V, 50/60Hz | ||

| Safety Devices | Thermo-over relay, Air pressure switch, Full load buzzer, Timer, Control fuse, Rotary valve sensor, Burner flame sensor, Over-heat sensor | ||

| Item | PHS-320B | ||

| Heat Source | SUNCUE Biomass Furnace BB-18, SUNCUE Rice Husk Furnace SB | ||

| Capacity Approx. kg | Paddy 1 liter=560g | 7,800~32,000 | |

| Wheat 1 liter=680g | 9,600~38,800 | ||

| Corn, Animal Feed 1 liter=690g | 9,600~39,400 | ||

| Dimension L(A)×W(B)×H(C) mm | Without CL-10 | 6,671×4,871×13,410 | |

| With CL-10 | Horizontal Type | 9,001×4,871×13,410 | |

| Vertical Type | 8,091×4,871×13,410 | ||

| Net Weight Approx. kg | Without CL-10 | 6,600 | |

| With ???????CL-10 | Horizontal Type | 7,642 | |

| Vertical Type | 7,943 | ||

| Required Thermal Energy per unit | Paddy ? Wheat Approx. Kcal/hr | 83,000~330,000 Ambient Temp. +10~40°C | |

| Corn ? Animal Feed Approx. Kcal/hr | 560,000 Ambient Temp. +65°C | ||

| Power Consumption kW | Without CL-10 | 16.84 | |

| With ???????CL-10 | 24.44 | ||

| Function Paddy | Loading Approx. mins | 55 | |

| Discharging Approx. mins | 50 | ||

| Drying Rate %/hr | 0.5~1.5 | ||

| Electricity | 3P, 220V/380V/415V/440V, 50/60Hz | ||

| Safety Devices | Thermo-over relay, Air pressure switch, Full load buzzer, Timer, Control fuse, Rotary valve sensor | ||

| Item | PHS-320G | |||

| Heat Source | LPG | NG | ||

| Max. Combustion Approx. | 41.6 kg/hr≒450kW | 45.5m3/hr≒450kW | ||

| Type | Gun type | |||

| Capacity Approx. kg | Paddy 1 liter=560g | 7,800~32,000 | ||

| Wheat 1 liter=680g | 9,600~38,800 | |||

| Corn, Animal Feed 1 liter=690g | 9,600~39,400 | |||

| Dimension L(A)×W(B)×H(C) mm | Without CL-10 | 5,871×4,871×13,410 | ||

| With CL-10 | Horizontal Type | 8,201×4,871×13,410 | ||

| Vertical Type | 7,291×4,871×13,410 | |||

| Net Weight Approx. kg | Without CL-10 | 6,360 | ||

| With ???????CL-10 | Horizontal Type | 7,402 | ||

| Vertical Type | 7,703 | |||

| Power Consumption kW | Without CL-10 | 13.8 | ||

| With ???????CL-10 | 21.4 | |||

| Function Paddy | Loading Approx. mins | 55 | ||

| Discharging Approx. mins | 50 | |||

| Drying Rate %/hr | 0.5~1.5 | |||

| Electricity | 3P, 220V/380V/415V/440V, 50/60Hz | |||

| Safety Devices | Thermo-over relay, Air pressure switch, Full load buzzer, Timer, Control fuse, Rotary valve sensor, Burner flame sensor, Over-heat sensor | |||

| Item | PHS-320S | |||||

| 7 | 12 | |||||

| Heat Source | Steam | |||||

| Capacity Approx. kg | Paddy 1 liter=560g | 7,800~32,000 | ||||

| Wheat 1 liter=680g | 9,600~38,800 | |||||

| Corn, Animal Feed 1 liter=690g | 9,600~39,400 | |||||

| Dimension mm | Without CL-10 | Length(A) | 5,497 | 5,846 | ||

| Width(B) | 4,871 | 4,871 | ||||

| Height(C) | 13,410 | 13,410 | ||||

| With CL-10 | Horizontal Type | Length(A) | 7,827 | 8,176 | ||

| Width(B) | 4,871 | 4,871 | ||||

| Height(C) | 13,410 | 13,410 | ||||

| Vertical Type | Length(A) | 6,917 | 7,266 | |||

| Width(B) | 4,871 | 4,871 | ||||

| Height(C) | 13,410 | 13,410 | ||||

| Net Weight Approx. kg | WithoutCL-10 | 6,465 | 6,530 | |||

| With CL-10 | Horizontal Type | 7,507 | 7,572 | |||

| Vertical Type | 7,808 | 7,873 | ||||

| Power Consumption kW | Without CL-10 | 13.1 | ||||

| With CL-10 | 20.7 | |||||

| Function Paddy | Loading Approx. mins | 50 | ||||

| Discharging Approx. mins | 55 | |||||

| Drying Rate %/hr | 0.6~1.0 | |||||

| Applicable Region | Regular | Cold | ||||

| Applicable Grains | Paddy, Wheat | Paddy, Wheat, Corn | ||||

| Temp. Increase Range Ambient Temp. | +15~45°C | +15~70°C | ||||

| Boiler Capacity Approx. ton/hr | 1.2 | 2.4 | ||||

| Boiler Pressure Approx. kg/cm² | 7 | |||||

| Electricity | 3P, 220V/380V/415V/440V, 50/60Hz | |||||

| Safety Devices | Thermo-over relay, Air pressure switch, Full load buzzer, Timer, Control fuse, Rotary valve sensor | |||||

Dimensions